The labor cost that can be physically and conveniently traced to a unit of finished product is called direct labor cost or touch labor cost. Examples of direct labor cost include labor cost of machine operators and painters in a manufacturing company. Like direct materials, it comprises of a significant portion of total manufacturing cost.

Applying Non-Manufacturing Costing Methods

These costs have two components— selling costs and general and administrative costs —which are described next. Manufacturing costs initially form part of product inventory and are expensed out as cost of goods sold only when the inventory is sold out. Non-manufacturing costs, on the other hand, never get included in inventory rather are expensed out immediately as incurred. This is why the manufacturing costs are often termed as product costs and non-manufacturing costs are often termed as period costs. Examples of marketing and selling costs include advertising costs, order taking costs and salaries of sales persons etc. Examples of administrative costs include salaries of executives, accounting costs, and general administration costs etc.

Only 2 GST Rates Now – Relief for Consumers and Businesses

This is especially true for specific product-related commissions and promotions. Manufacturing costs refer to those that are spent to transform materials into finished goods. Manufacturing costs include direct materials, direct labor, and factory overhead. Analyzing Overhead costs in Service-Based Organizations is a crucial aspect of understanding the total cost of providing a service nonmanufacturing costs or performing a function. In this section, we will delve into the various perspectives and insights related to overhead costs in service-based organizations. PepsiCo, Inc., produces more than 500 products under several different brand names, including Frito-Lay, Pepsi-Cola, Gatorade, Tropicana, and Quaker.

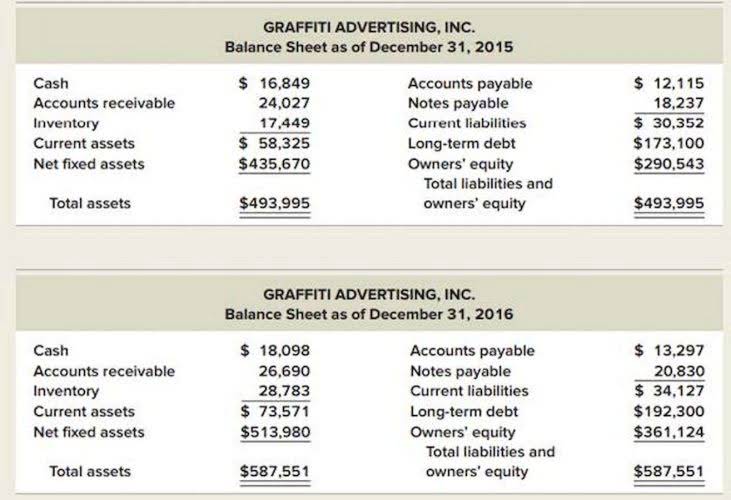

Presentation of Manufacturing and Nonmanufacturing Costs in Financial Statements

The second part of the necessary entry will be a credit to a liability account. Direct materials are raw materials that become an integral part of the finished goods. Items such as plastic parts, metal parts and paint can be examples of manufacturing inventory. If the net realizable value of https://cma6.online/bigdata/?p=1215 the inventory is less than the actual cost of the inventory, it is often necessary to reduce the inventory amount. We recommend taking our Practice Quiz next, and then continuing with the rest of our Nonmanufacturing Overhead materials (see the full outline below).

Manufacturing overhead cost:

We use the term nonmanufacturing overhead costs or nonmanufacturing costs to mean the Selling, General & Administrative (SG&A) expenses and Interest Expense. Under generally accepted accounting principles (GAAP), these expenses are not product costs. (Product costs only include direct material, direct labor, and manufacturing overhead.) Nonmanufacturing costs are reported on a company’s income statement as expenses in the accounting period in which they are incurred. Distinguishing between the two categories is critical because the category determines where a cost will appear in the financial statements.

- Note 1.48 “Business in Action 1.6” provides examples of nonmanufacturing costs at PepsiCo, Inc.

- All manufacturing costs that are easily traceable to a product are classified as either direct materials or direct labor.

- Insurance Expense, Wages Expense, Advertising Expense, Interest Expense are expenses matched with the period of time in the heading of the income statement.

- Remember that non-manufacturing costs are not just expenses—they represent investments in the organization’s growth and sustainability.

- Analyzing overhead costs in service-based organizations is essential for understanding the total cost of providing services or performing functions.

- MasterCraft records these manufacturing costs as inventory on the balance sheet until the boats are sold, at which time the costs are transferred to cost of goods sold on the income statement.

- We focus on financial statement reporting and do not discuss how that differs from income tax reporting.

Remember, these practices are just a starting point, and their applicability may vary depending on your specific industry or function. By implementing these strategies and adapting them to your unique circumstances, you can effectively manage non-manufacturing costs and optimize your overall operations. Table 1.2 provides several examples of manufacturing costs at https://www.bookstime.com/articles/financial-risk Custom Furniture Company by category.

- In summary, the section on “Cost Measurement Techniques for Service Industries” explores approaches such as activity-based costing, time-driven activity-based costing, customer profitability analysis, and cost benchmarking.

- By analyzing these costs, organizations can make informed decisions, allocate resources efficiently, and improve overall performance.

- Inventory in a manufacturing company is items purchased (or created) by a company for (a) production of other parts (raw materials or work-in-process) or (b) selling to customers (finished goods).

- When finished goods are sold, the cost of goods sold is transferred to the income statement (expensed) and matched with the sales revenue.

- Some valuable items that cannot be measured and expressed in dollars include the company’s outstanding reputation, its customer base, the value of successful consumer brands, and its management team.

- Table 2.2 provides several examples of manufacturing costs at Custom Furniture Company by category.

This account is a non-operating or “other” expense for the cost of borrowed money or other credit. The amount of interest expense appearing on the income statement is the cost of the money that was used during the time interval shown in the heading of the income statement, not the amount of interest paid during that period of time. You should consider our materials to be an introduction to selected accounting and bookkeeping topics (with complexities likely omitted). We focus on financial statement reporting and do not discuss how that differs from income tax reporting. Therefore, you should always consult with accounting and tax professionals for assistance with your specific circumstances. Next, you will need to allocate the cost of the activities to the individual products.